Sheet Metal Fabrication Services

Custom engineering and manufacturing services from prototypes to on demand production of sheet metal parts. Low-cost sheet metal fabrication solution for you.

- Free quotation with DFM review in 12 hours

- Lead time as fast as 3 days

- ISO 9001:2015 certificated

Sheet Metal Prototyping Fabrication

CNC Expert’s custom sheet metal prototyping services offer a fast and cost-effective solution for your projects. Services including bending, punching, cutting standard gauge metal for both prototypes and low volume production runs. Sheet metal fabrication produces durable, end-use metal parts with a wide selection of materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy and robotics.

Laser Cutting

Intense lasers cut through 0.5mm to 20mm thick sheet metals to create high-grade prototype sheets for various parts.

Plasma Cutting

CNC plasma cutting is widely used in custom sheet metal services, it is especially suitable for custom cutting of thicker sheet metals.

Waterjet Cutting

High-pressure water jets cut through sheet metals without leaving burn marks, creating a superior edge that improves the aesthetic and performance of specific parts.

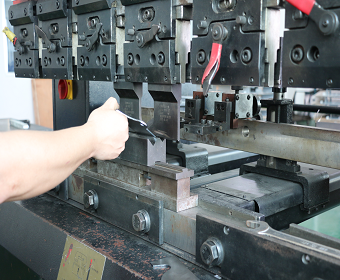

Bending

Sheet metal bending is used to shape steel, stainless steel, aluminum parts and custom sheet metal prototypes after the cutting process.

Sheet Metal Fabrication Materials

No matter the application and requirement of your sheet metal parts, you’ll find the right material when you trust CNC Expert. The following outlines some popular materials available for custom metal fabrication.

Aluminum

Commercially, aluminum is the most sought-after material for sheet metal manufacturing. Its popularity is due to its adaptive qualities and its high thermal conductivity and low resistance rates. Compared to steel—another common sheet metal material—aluminum is more cost-effective and has a higher rate of production. The material also generates the least amount of waste and can easily be reused.

Copper

Copper is a broadly used sheet metal fabrication material in many industries as it offers good malleability and ductility. Copper is also well suited for sheet metal fabrication because of its excellent heat conduction properties and electrical conductivity.

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Steel

Steel offers a number of beneficial properties for industrial applications, including rigidity, longevity, heat resistance and corrosion resistance. Steel sheet metal is ideal for producing complex designs and parts that require extreme precision. Steel is also cost-efficient to work with and has excellent polishing properties.

Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of 10% chromium by weight. The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Bead Blasting

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.