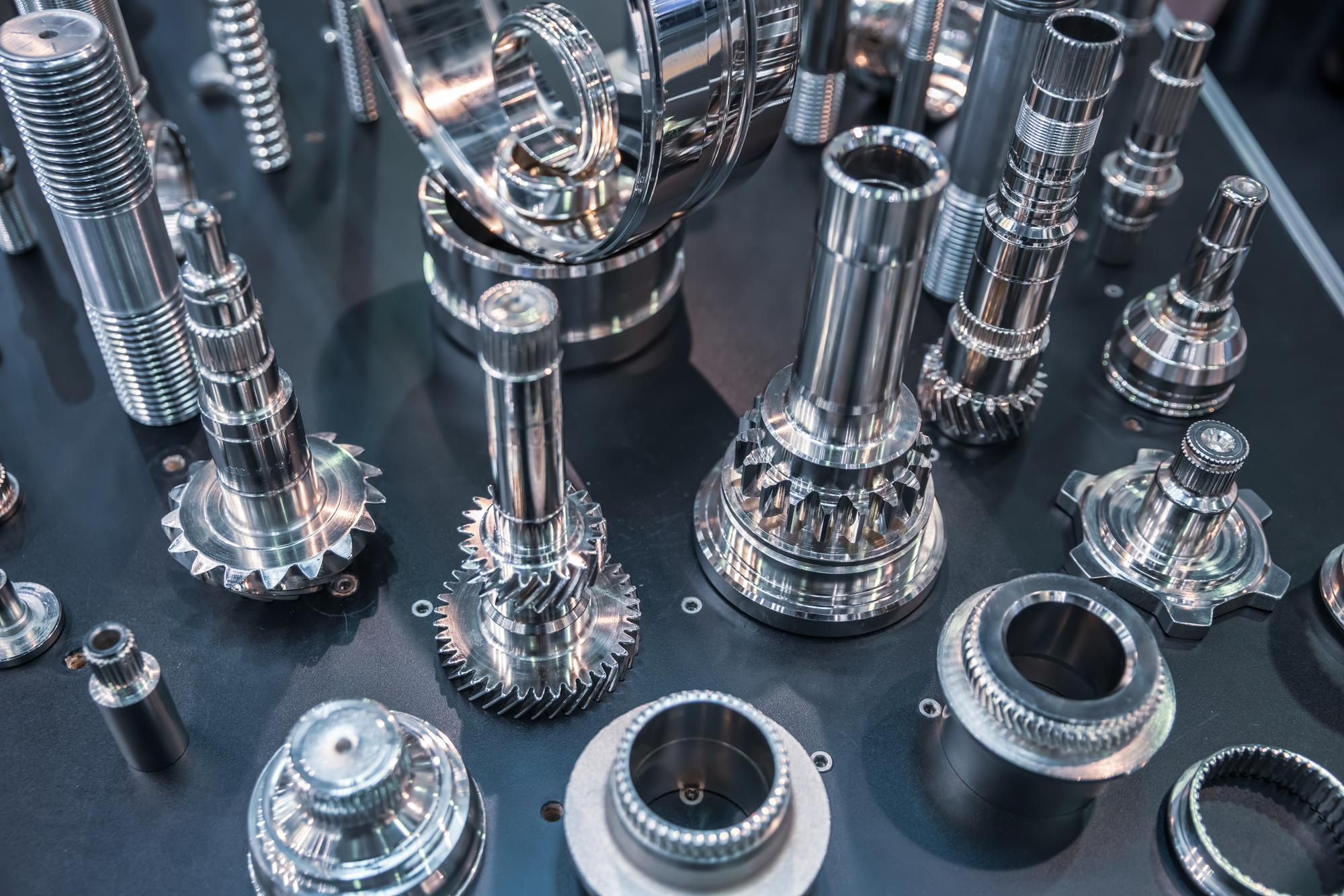

Understanding Fillets and Chamfers in CNC Machining

CNC machining is a precise manufacturing process where computer-controlled machines carve out shapes from solid materials based on digital designs. The importance of edge finishing in CNC parts cannot be overstated, as it can significantly influence the performance, safety, and aesthetics of the final product. Two common methods employed for this purpose are fillets and chamfers. Fillets refer to the rounding off of internal or external corners, which enhances part strength by reducing stress concentrations. Chamfers, on the other hand, create straight bevels usually at 45-degree angles, facilitating easier assembly and reducing sharp edges. While both techniques serve to improve the functionality and longevity of machined components, their application depends on design requirements and intended use.

Defining Fillets

A fillet in CNC machining refers to a rounding of an interior or exterior corner of a part. This feature is created by blending two surfaces with a smooth curve instead of a sharp edge, enhancing the part’s aesthetic appeal and structural integrity. Fillets distribute stress over a broader area, reducing peak stress concentrations that can lead to cracks or fractures under load. Additionally, fillets facilitate easier cleaning and handling, minimizing sharp edges that could cause injury. For instance, in aerospace components where durability and safety are paramount, strategically placed fillets help resist fatigue failure resulting from high-frequency vibrations and dynamic loads.

Defining Chamfers

A chamfered edge in CNC machining is a beveled edge that typically connects two surfaces at an angle, as opposed to a rounded corner known as a fillet. When engineers opt for chamfers over other finishes, such as fillets or straight edges, they gain several advantages. For one, chamfering can facilitate easier assembly of parts, since the angled surface can guide fasteners into place more smoothly than abrupt corners would. Additionally, chamfered edges often require less machining time compared to fillets, making them a cost-effective choice. They are particularly beneficial in reducing stress concentration and preventing fractures by eliminating sharp corners, thus improving overall part durability. Furthermore, with a simpler geometry, chamfers are generally easier to measure and inspect, enhancing quality control processes.

Differences Between Fillets and Chamfers

In CNC machining, the geometrical distinction between fillets and chamfers significantly influences both part strength and manufacturing considerations. A fillet is a rounded corner or edge created by a concave curve transition between two surfaces, often enhancing the part’s ability to resist stress concentration – a critical aspect in fatigue-sensitive applications. On the other hand, a chamfer is an angular cut typically at 45 degrees that connects two edges. While this bevel can ease assembly by removing sharp corners, it may not distribute stresses as effectively as a fillet. When considering manufacturing efficiency and costs, chamfers are generally simpler and less expensive to produce since they require fewer tooling passes compared to fillets, which might need specialized tools and multiple passes to achieve the desired radius.

Common Applications of Fillets

In the realm of CNC machining, fillets are frequently employed to enhance the strength and distribute stress evenly across corners of machined parts. They are favored in high-stress applications where right angles could become focal points for cracks or structural failures. For instance, within the aerospace industry, fillets are integral to the design of wing components; they help to alleviate stress concentrations that occur due to drastic changes in airflow pressure during flight. The smooth transition that a fillet provides between two surfaces minimizes the risk of material fatigue, thus contributing significantly to the safety and longevity of the aircraft’s critical components.

Common Applications of Chamfers

Chamfers are an integral feature in CNC machining, frequently implemented to not only ease the assembly of machined parts but also to reduce stress concentrations that could lead to part failure. A typical application includes edge preparation for critical components within aerospace applications, where chamfers allow for smoother transitions and better load distribution when components interface. For instance, chamfered edges on aerodynamic body flanges can significantly mitigate the risk of crack propagation due to cyclic loads during flight operations—enhancing overall structural integrity and safety. This beveling technique ensures a uniform surface finish which is vital in maintaining aerodynamic efficiency and reducing drag over the connections, proving the practical importance of chamfers in high-performance environments.

Choosing Between Fillets and Chamfers

In CNC machining, the selection between fillets and chamfers primarily hinges on design requirements and functional purpose of the machined part. A fillet, which is a convex curve joining two surfaces, is often used when high strength is needed at edges or corners, as its continuous curvature reduces stress concentration. In contrast, a chamfer—a beveled edge that connects two surfaces—facilitates easier assembly with mating parts, is quicker to machine, and can help in reducing sharp edges that might otherwise pose safety concerns. When making this decision, one must consider factors such as whether the part will undergo significant physical stress, which would favor fillets, or if ease of assembly and manufacturing speed are priorities, suggesting the use of chamfers. For example, a fillet may be preferable for aerospace components where structural integrity around curves is crucial, whereas chamfers could better serve an assembly requiring frequent disassembly.

Understanding the Functional Differences Between Fillets and Chamfers in CNC Machining

In CNC machining, fillets and chamfers serve distinct functions. A fillet is a rounded connecting surface that typically reduces stress concentration, which can be critical for enhancing the durability of parts subject to dynamic loads. Its primary function lies in offering smoother transitions between surfaces to withstand cyclical stresses better. On the other hand, a chamfer is an angled or beveled edge intended to facilitate easier assembly, protect against sharp edges, or allow clearance for fasteners or mating parts. Both fillets and chamfers can coexist on a single part serving their unique purposes—for instance, using chamfers to ease assembly where needed while employing fillets to bolster structural integrity elsewhere.

The cost implications of choosing fillets over chamfers—or vice versa—often stem from the complexity involved in machining each feature; complex contours of a fillet might require more sophisticated tooling, whereas chamfers are usually simpler and faster to produce. Moreover, when considering structural integrity, fillets generally add more robustness due to their curved shape distributing stress over a wider area compared to the linear nature of chamfers. However, there isn’t a ‘one-size-fits-all’ when it comes to sizing these features in CNC machining; sizes tend to be application-specific and tailored based on design requirements like load conditions and assembly constraints, though some industry standards commonly guide initial decisions.