Injection Molding Service

Low-Volume and Mass Production in One Place

- Thermoplastic Injection Molding

- Thermoset Silicone Injection Molding

- Metal Injection Molding

One-Stop Injection Molding Solutions

Need to quickly test out the market with low-volume parts? Or want to create large quantities of production parts? Then you can’t go wrong with our injection molding services. At CNC Expert, we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability and functionality fast. We also offer metal or plastic injection molding for your high-volume production needs.

Do you need rapid tooling, mass production mold making, or end-use injection molding with tight tolerances? Our team of experienced specialists can offer a cost-effective solution at each stage.

Why Choice Our Injection Molding Service

There are huge numbers of injection molding providers. Why should you choose CNCExpert.Net as your injection molding supplier? Here are the top 3 reasons:

1. Experienced Engineers

Our injection molding engineers have rich experience after handling thousands of projects; whichever parts they come across, they can get the correct parameters immediately.

2. Advanced Facilities

We can make the most precise moldings using imported and top-brand local injection molding machines.

3. Unlimited Capacities

Aside from our in-house facilities, we have built up strong networks with our partners. Full fleets of metal and plastic injection molding machines, from 10 to 1000 tons are ready for your orders without delay.

Our Injection Molding Capabilities

From plastic prototyping to production molding, CNCExpert.Net’s custom injection molding service is ideal for the manufacturing of competitive pricing, high-quality molded parts in a fast lead time. Strong manufacturing facilities with powerful, precise machines ensure the same mold tool for creating consistent parts. Better yet, we provide free expert consultation on each injection molding order, including mold design advice, materials&surface finishes selection for your end-use applications, and shipping methods.

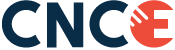

Mold Tooling

With our experience and advanced machinery, we excel at designing and manufacturing a series of plastic injection molds adjusted to your tolerance and cost.

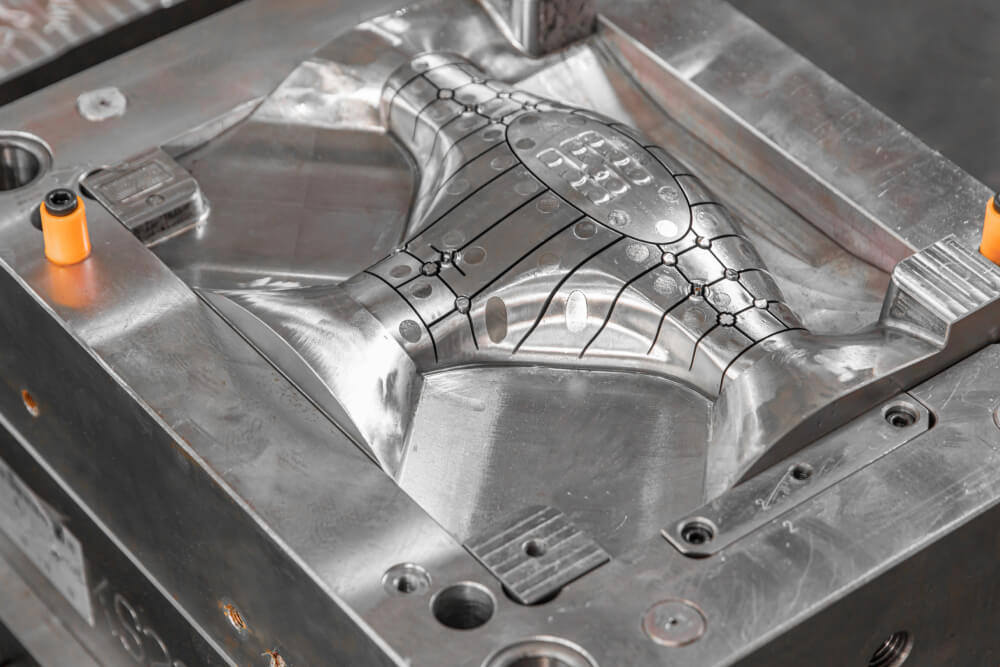

Plastic Injection Molding

Our plastic injection molding process uses precise machinery to shoot molten resin into a mold to become a final production-grade thermoplastic part.

Over Molding

Covering plastic, metal, and rubber over each other via chemical bonding, our overmolding reduces assembly time and gives our parts greater strength and flexibility.

Insert Molding

Insert molding is the process of molding thermoplastic material around a preformed component to create a finished part that incorporates multiple materials.

Materials for Injection Molding

If you are considering manufacturing your parts with CNC machining, it is important to know what kind of materials and finishes can be applied to your CNC machined parts. CNCExpert.Net, located in China, is not just a CNC shop; we can also apply all types of finishes to CNC prototype parts and production parts thanks to our surface finishing partners. Need custom CNC parts with a high-quality appearance? CNC Expert is here to help.

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel

P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum

6061, 5052, 7075

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

- Acetal polyoxymethylene (POM)

- Acrylonitrile butadiene styrene (ABS)

- Nylon 66 (PA66)

- Glass-filled, polyamide (PA-GF)

- High-density polyethylene (HDPE)

- Low-density polyethylene (LDPE)

- Polybutylene terephthalate (PBT)

- Polycarbonate (PC)

- Glass-filled polycarbonate (PC-GF)

- ABS polycarbonate (PC-ABS)

- Polyethylene terephthalate (PET)

- Polymethyl methacrylate (acrylic) (PMMA)

- Polyphenylene sulfide (PPS)

- Polypropylene (PP)

- Polystyrene (PS)

- Polystyrene + polyphenyl ethers (PS-PPE)

- Thermoplastic elastomer (TPE)

- Thermoplastic vulcanizates (TPV)

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts:

- UV absorbers

- Colorants

- Flame retardants

- Glass fibers

- Plasticizers

What is Injection Molding?

Injection molding processes make plastic parts via the injection of molten plastic — typically a thermoplastic — into metal injection molds, usually made from steel or aluminum.

The machine feeds raw material into the mold itself, effectively a negative impression of the final part, which consists of two sections: an injection (A) mold and an ejector (B) mold.

The space between the two sections is the mold cavity, into which material is injected.

Although capable of producing a wide range of parts, injection molds have some design constraints. Plastic injection molded parts must have narrow walls. They should avoid overhanging features and have some degree of draft (tapered sides) so that the molded part can be ejected from the mold.

Injection molding is principally used with plastics and thermoplastics in particular. Thermoplastics are polymers that soften at an elevated temperature (at which point they can be freely injected into a mold) and then return to a solid state after cooling. Injection molding also works with thermosets, which can be cured to make a solid but cannot then be melted back into a liquid. Less common are elastomers.