In the world of CNC machining, understanding the various methods for processing part surfaces is crucial. Each technique has its unique advantages and is suited for different applications. Let’s dive into some conventional methods of machining part surfaces, focusing on rotational and planar surfaces, with practical insights and a personalized touch.

Machining Rotational Surfaces

Turning Outer Cylindrical Surfaces

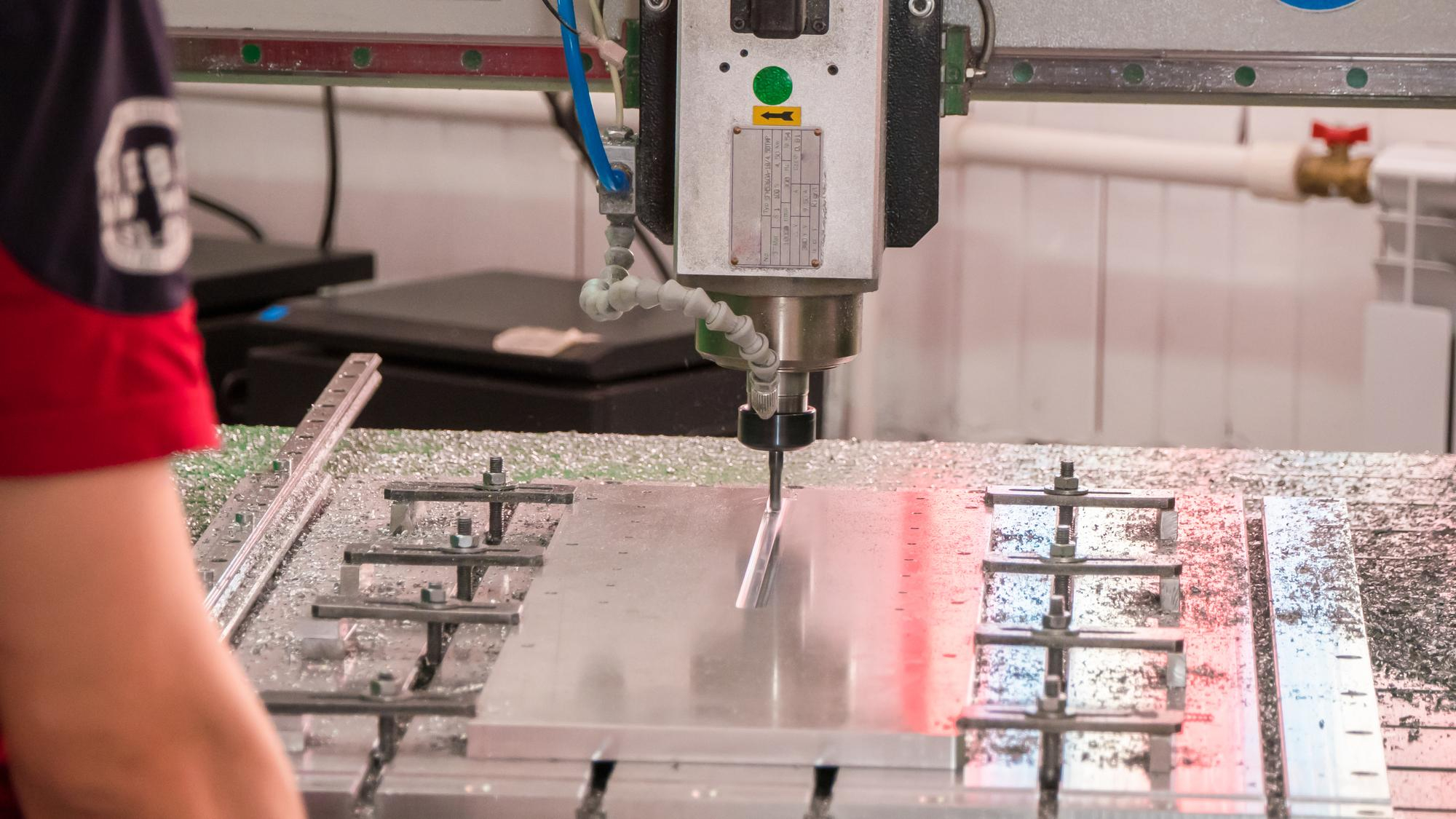

Turning is one of the most common machining processes. It involves rotating the workpiece while a cutting tool moves linearly to shape the material. This method is highly efficient for creating cylindrical parts and can achieve excellent dimensional accuracy and surface finish.

Drilling, Reaming, Boring, and Honing Holes

Hole machining is a critical step in CNC machining, involving various methods:

- Drilling: Using a twist drill to create holes with diameters typically less than 80mm. Drilling can be done on lathes, drilling machines, or boring machines. The main characteristics of drilling include poor rigidity of the drill, poor guidance, difficulty in chip removal, and high cutting temperatures.

- Reaming: Reaming uses a reamer to enlarge existing holes, improving dimensional accuracy and surface finish. It is typically used as a semi-finishing process for holes and is common for enhancing the precision of drilled, cast, or forged holes.

- Boring: Boring uses a single-point cutting tool to further process holes that have been forged, drilled, or cast. Boring machines are the primary equipment for this process, capable of machining large holes and ensuring the shape, size, and positional accuracy of the holes.

- Honing: Honing is used for the final finishing of holes, providing high precision and surface quality.

Grinding and Finishing

Grinding is used to achieve a high degree of surface finish and dimensional accuracy. It involves an abrasive wheel removing small amounts of material. For even finer finishes, polishing techniques like honing and lapping can be applied.

Challenges in Hole Machining

Machining holes presents unique challenges:

- Tool Rigidity: Drills and reamers can be prone to deflection, especially in deep hole machining.

- Heat and Chip Removal: The confined space within a hole makes it difficult to dissipate heat and remove chips, affecting surface quality and precision.

- Tool Wear: Manufacturing and maintaining the precision of cutting tools is crucial, as tool wear directly impacts hole accuracy.

Ensuring Dimensional Accuracy in Holes

Different methods ensure the dimensional accuracy of holes:

- Drilling: The initial step, often followed by more precise operations.

- Reaming: Used to refine the size and finish of the hole.

- Boring: Ensures alignment and precision, especially for larger or deeper holes.

A Table of Hole Machining Methods and Their Characteristics

| Method | Accuracy (IT) | Surface Roughness (Ra, μm) | Application |

|---|---|---|---|

| Drilling | IT13-IT11 | 50-12.5 | General purpose, initial hole creation |

| Reaming | IT10-IT9 | 6.3-3.2 | Refining hole size and finish |

| Boring | IT8-IT7 | 1.6-0.8 | High precision and alignment |

| Honing | IT7-IT5 | 0.2-0.025 | Final surface finish, high precision |

| Grinding | IT6-IT5 | 0.8-0.2 | High precision, hard materials |

| Lapping | IT5-IT3 | 0.1-0.008 | Ultra-fine surface finish and precision |

Machining Planar Surfaces

Turning, Planing, and Milling

- Turning: Used for machining the end faces of cylindrical parts. It’s suitable for achieving high flatness and parallelism. Dimensional tolerance is generally IT8

IT7, with a surface roughness of Ra 6.31.6. - Planing: Ideal for large, flat surfaces. The workpiece moves back and forth under a stationary cutting tool. Common machines include the shaper and the planer. Planing is adaptable but has lower productivity and precision, with dimensional tolerance of IT9

IT8 and surface roughness Ra 6.31.6. - Milling: One of the most versatile methods for machining flat surfaces. It uses rotary cutters to remove material from a workpiece moving along multiple axes. Milling can be categorized into end milling and peripheral milling. End milling provides higher quality and productivity, while peripheral milling is more adaptable for various features.

Grinding and Surface Finishing

Grinding is essential for finishing flat surfaces with high precision. For even better finishes, polishing methods like lapping can be applied. These processes are critical for applications requiring extremely smooth and flat surfaces, such as gauge blocks and optical components.

Grinding

Used for precision finishing of flat surfaces, grinding machines include horizontal and vertical surface grinders. Grinding methods include surface grinding and cylindrical grinding. Surface grinding is preferred for small, high-precision parts, while cylindrical grinding is suitable for larger, less precise parts.

Lapping and Scraping

- Lapping: Lapping is a surface finishing method usually performed after grinding. It provides high accuracy and surface quality, with tolerances up to IT5

IT3 and surface roughness Ra 0.10.008 μm. - Scraping: Scraping is a manual process using a scraper to remove thin layers of metal from the workpiece surface. It is often used after precision planing and milling to achieve high-quality surfaces with Ra 0.8~0.2 μm.

Machining Complex Surfaces

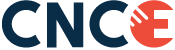

Complex surface machining includes forming surfaces, thread machining, and gear machining.

Forming Surface Machining

Forming surface machining uses forming tools or specific relative motions between the tool and the workpiece. Common methods include forming tools and template methods, suitable for a wide range of sizes.

Thread Machining

Thread machining includes tapping, threading, milling, grinding, and rolling. The precision and surface quality of threads directly affect their performance in connections and transmissions.

Gear Machining

Gear machining primarily involves hobbing, shaping, and gear finishing. The selection of gear machining methods depends on the required precision, which is categorized into 12 levels. Common gear machining methods include shaving, honing, and grinding.

Selecting the Right Machining Process

Choosing the right machining process depends on various factors, including the material, size, and required precision of the part. Here are some practical tips:

- For Large Flat Surfaces: Planing and milling are excellent choices. Planing is great for very large parts, while milling offers versatility and precision for medium to large parts.

- For High Precision: Grinding and honing are ideal for achieving tight tolerances and smooth finishes.

- For High Volume Production: Methods like broaching (for holes) and high-speed milling can significantly boost productivity.

By understanding these conventional machining methods and their specific applications, you can make informed decisions that enhance the efficiency and quality of your CNC machining projects. Remember, the right method can make all the difference in achieving the desired precision and surface finish for your parts.

4o