CNC Machining Service

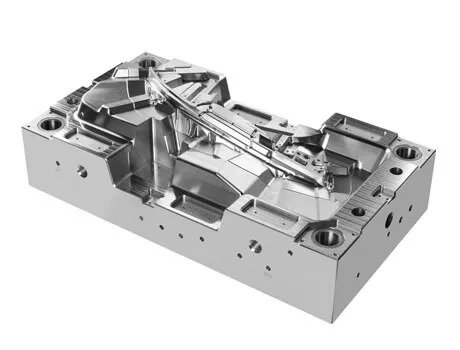

Custom CNC Machining Parts in Plastic and Metal

Delivery in as fast as 5 days

- 1 off CNC Prototype

- 100K+ Mass Production Machining

- Tolerance as tight as ±0.01 mm

Full Capabilites CNC Machining

CNCExpert.Net provides a variety of online CNC machining services including milling, turning, EDM, wire EDM and surface grinding. With precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team, we can handle all types of CNC machining parts in both metal and plastic materials. Whatever you need prototypes or production parts, our CNC machining service will be your best choice. Request your online quote today to get your machining parts done in as fast as 5 days!

CNC Machining Processes

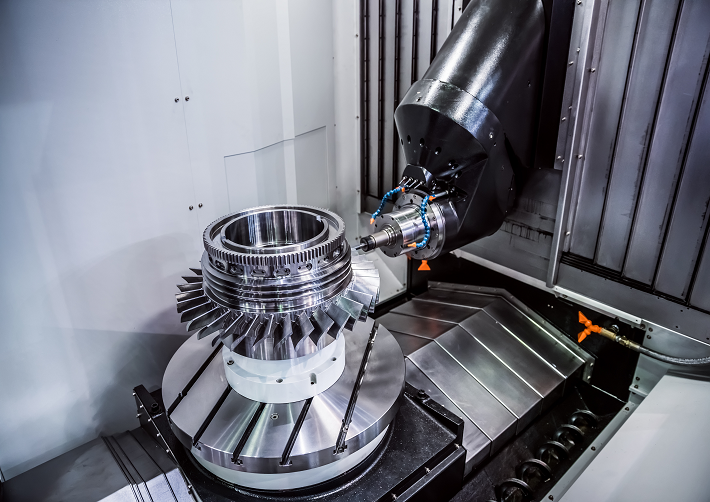

3 - 5 Axis Machining

Our muliple axis machining capabilities enable us to provide precise parts with complex geometry. CNC Expert’s experienced team can help bring your ideas to life, from rapid prototypes to end-use parts for safety-critical applications.

CNC Milling

CNC milling is a subtractive process that using 3-, 4-, & 5-axis milling machines with various of cutting tools to remove materials from solid plastic and metal blocks into final parts with different geometries as designed.

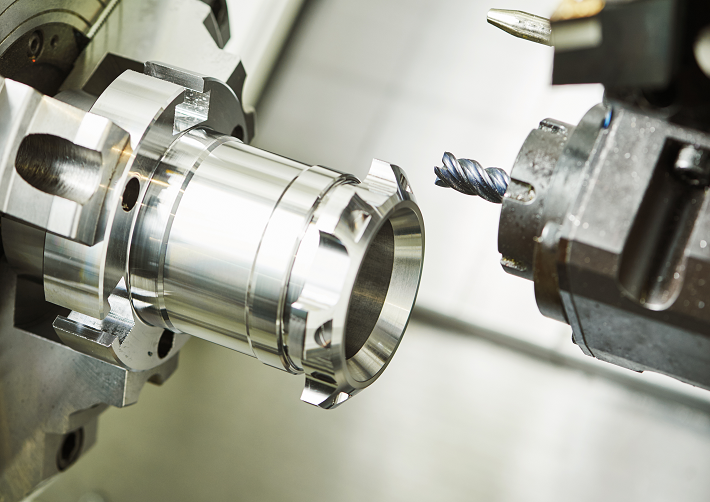

CNC Turning

CNC turning is a more efficient method to manufacture round shaped components from plastic and metal bars or tubes, such as shafts, worms. Combines with live tooling, milled geometries can be done in the meantime.

Why Choice Us

Instant Quote

At CNCExpert.net, we understand the importance of prompt communication and response. That's why we strive to deliver quotations within hours of receiving a clear RFQ.

Maximize Your Network Capacity

Our in-house facilities, combined with our extensive network of rapid manufacturing partners, give us the flexibility to handle any project with ease. Our massive network capacity ensures that we can deliver your projects fast.

Accelerate Your Turnaround

Our unlimited capacity, experienced engineers, and flexible production system allow us to create prototypes and production parts in record time. Trust us to help you meet your tightest deadlines.

Benefit from 12 Years of Experience

With 12 years of experience in rapid prototyping and manufacturing, our engineers have gained a wealth of knowledge and expertise. No project is too complex for us to handle.

30,000+ Satisfied Projects

Over the past 12 years, we have successfully delivered over 30,000 projects to customers worldwide, earning numerous positive reviews along the way.

2000+ Loyal Customers

Customer satisfaction is at the heart of everything we do. Our goal is to ensure that each and every customer is happy with our reliable quality, fast turnaround, and exceptional services. We believe that every new customer has the potential to become a long-term partner."

Material & Finishes

If you are considering manufacturing your parts with CNC machining, it is important to know what kind of materials and finishes can be applied to your CNC machined parts. CNCExpert.Net, located in China, is not just a CNC shop; we can also apply all types of finishes to CNC prototype parts and production parts thanks to our surface finishing partners. Need custom CNC parts with a high-quality appearance? CNC Expert is here to help.

Plastic

ABS, PC, ABS+PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK.

Metal

Aluminum, Steel, Stainless Steel (17-4, Inconel 625 & 718), Magnesium, Titanium, Zinc, Brass, Bronze, Copper.

These are the most common materials for CNC prototyping and production parts. Besides that, we can work with any type of machinable plastic and metal we can purchase from the stock market.

What’s more

We are able to create a custom plastic block or bar for the material such as PA GF50, PPS GF50. To discover further plastic materials we can do, please contact our team.

As-Machined: The most popular and cost efficient way for inner functional components. Fine and even tool path is also good for aspect parts.

Bead Blasted: The part is left with a matt appearance. Range of 120 to 320 beads allows us to create different roughness to the surface.

Anodized: Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and blue are most common—and is usually associated with low silicone element series of aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Powder Coat: This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

CNC Machining Tolerances

With a wide range of CNC machines, we are able to provide stand tolerance CNC machined parts with the most economic price and super precision machined parts for the high-end products. When working with CNC Expert, we guarantee all parts will be made accordingly to your specification. If 2D drawings are not available, you can also indicate with ISO 2678 as well.

Aside from standard tolerance CNC parts such as ISO2678M or ISO2678F, CNC Expert also offers high-precision CNC machining parts. With high precision milling & turning machines, we are able to catch super tight tolerance for prototype machining & production. After being in the manufacturing industry for over 10 years, we discovered a simple formula to produce precision parts Precision machines + Precision heart = Precision parts. CNC Expert has a wide range of CNC machines and experienced engineers who never compromise with tolerance or part quality.