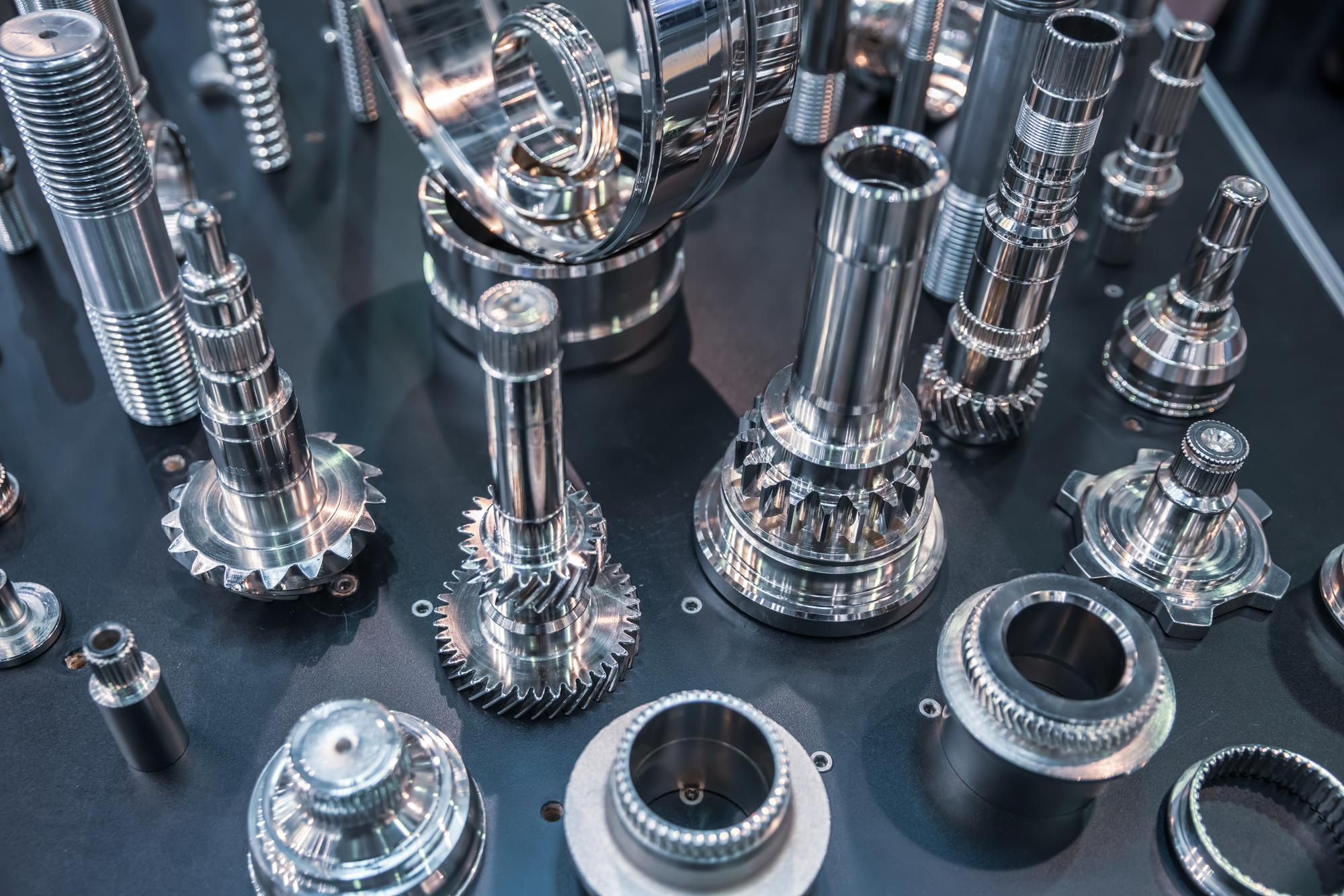

Introduction to Casting Processes

Casting is a fundamental manufacturing process wherein molten material, often metal, is poured into a mold with a hollow cavity of the desired shape and then allowed to solidify. This technique plays a critical role in industrial production as it enables the creation of complex parts that may be challenging or impossible to achieve through other methods. With its ability to produce intricate shapes and internal geometries, casting forms the backbone for fabricating key components used across various sectors, including automotive, aerospace, and construction. Its significance lies not just in versatility but also in economic efficiency for mass production of parts with uniform quality and properties.

Sand Casting Process

The sand casting process is a time-honored method widely used for producing metal components with complex geometries. Initially, a pattern that replicates the final product is crafted from wood or metal and embedded into special molding sand to create an imprint, forming a mold cavity. Separate molds are then prepared for the molten metal. The sand itself must be bonded together using clay or chemical binders to withstand the high temperatures of melting metals. After the sand mold has been created, molten metal is poured into the cavity where it cools and solidifies into the shape of the pattern. Excess material, including the gating system (sprues and runners), is removed after cooling, delivering a rough product often requiring further finishing processes such as grinding or machining. This technique suits a vast range of products from engine blocks to intricate decorative hardware, due to its flexibility in handling various metals and alloys along with the capacity to produce large-scale parts.

Investment Casting Precision Capabilities

Investment casting, also known as lost-wax casting, is a manufacturing process renowned for its ability to produce components with exceptional accuracy and intricate details. This technique involves creating a wax model or pattern that mirrors the final product. The model is encased in a refractory ceramic material that hardens into a mold. Once the ceramic shell is solidified, the wax is melted away, leaving a cavity that is filled with molten metal to form the part. Investment casting is favored for producing parts requiring tight tolerances, complex geometries, and smooth surface finishes without additional machining. An example of its precision capability is seen in the aerospace industry, where investment cast components are utilized due to their reliability and the stringent dimensional accuracies demanded by this sector.

Permanent Mold Casting

Permanent mold casting, a process involving reusable molds typically made of metal, stands in contrast to expendable mold processes such as sand casting where the mold is destroyed after each use. The durability of a permanent mold allows for consistent dimensions and smoother finishes on cast parts compared to those from expendable molds. This method involves preheating the mold, pouring molten metal into it, then cooling and ejecting the solidified part. While less flexible than sand casting when it comes to design complexity or changes, permanent mold casting offers faster production cycles and is ideal for medium to high-volume production runs. For instance, aluminum alloy components utilized in automotive applications are often produced using this technique due to its efficiency and the quality of the surface finish.

Centrifugal Casting

The centrifugal casting process utilizes the principle of centrifugal force to produce cylindrical parts with uniform material properties. Molten metal is poured into a spinning mold, which generates a force that pushes the metal outward against the walls of the mold. This force ensures that any impurities or lighter inclusions are driven towards the center, from where they can be easily removed once the casting has solidified. The result is a dense and high-quality surface finish on the outer diameter, ideal for manufacturing components like pipes, bearings, and bushings. As an example, industries such as automotive and aerospace rely on this technique to create precision parts that demand enhanced mechanical performance.

Plaster Casting

Plaster casting is a versatile method often used when a high degree of accuracy and an excellent surface finish are required, without the need for additional machining. This process employs plaster of Paris as the mold material around a pattern that is typically made from metal or plastic. Once the mold dries, it creates a high-precision cavity for molten material to be poured into. Preferred for casting intricate parts, such as art sculptures, medical devices, and tools with delicate features, plaster casting stands out for its ability to capture fine details that other casting processes might miss. Though not suitable for large-scale production due to slower drying times and less heat resistance compared to sand casting, it remains ideal for smaller quantities of specialized components with complex geometries.

Shell Molding

Shell molding, also known as shell mold casting, stands out in the manufacturing world due to its precision and ability to create complex geometries with enhanced surface finish. This process involves first creating a shell mold from a mixture of sand and resin that is heated and formed around a patterned template. Once hardened, the shell serves as a highly detailed and stable mold for molten metal. The accuracy of this method allows intricate designs that are challenging or impossible to achieve through traditional sand casting techniques. As an example, shell molding is particularly advantageous when producing small to medium-sized metal parts necessitating fine features, such as gear housings or connecting rods, where precise dimensional control is crucial.

Ceramic Mold Casting

Ceramic mold casting, also referred to as the Shaw process, entails using a ceramic slurry to form a shell around a pattern made of wax or another disposable material. After hardening, the ceramic is capable of withstanding high temperatures without losing its shape. This process permits fine detailed castings with an excellent surface finish and is often employed for complex geometries that are hard to achieve via other methods. A practical application includes the production of parts such as turbine blades, used in aerospace industry, where precision and durability are paramount. In this technique, the wax model is encased in the slurry which, upon solidification, forms a robust mold enabling molten metal to be poured into extremely intricate shapes, achieving final components that demand minimal post-casting machining.

V-Process Casting

The V-process casting, also known as vacuum casting, is a precision casting process that uses a sand mold held together by a vacuum. The steps begin with placing a plastic film over the pattern and then frame. Sand is then carefully sieved onto the film-covered pattern until covered, followed by another sheet of plastic to create a sand mold once the vacuum is applied. The key aspect of this method lies in its ability to produce smooth, precise castings with thin walls and minimal finishing required, which makes it especially advantageous for intricate components typically utilized in aerospace applications or areas where tight dimensional tolerances are essential. After the molten material solidifies, the vacuum is released, causing the sand mold to collapse and making it easy to remove the casting without damaging delicate features.

Lost Foam Casting

Lost foam casting is a type of evaporative-pattern casting process that involves the use of a polystyrene foam pattern which is coated with ceramic refractory material and embedded into compacted sand. Upon pouring molten metal, the foam vaporizes and is replaced by the metal, faithfully reproducing the shape of the foam pattern. Industries such as automotive, aerospace, and engineering machinery reap benefits from this casting method due to its ability to produce complex geometries with precision, minimal machining, and reduced waste. For example, in the automotive sector, manufacturers utilize lost foam casting to create lightweight engine parts with intricate internal passages that would be difficult or impossible to achieve through traditional manufacturing techniques.

Squeeze Casting

Squeeze casting is an advanced technique that merges the advantageous characteristics of both forging and traditional casting processes. This method involves pouring molten metal into a preheated die, where it solidifies under high pressure applied throughout the cooling phase. The elevated pressure eliminates porosity by ensuring that any air or gases are squeezed out as the metal crystallizes. A distinct feature of squeeze casting is its ability to produce parts with superior density, excellent mechanical properties, and fine-grained microstructure compared to those produced through conventional casting methods. It’s particularly useful for creating components that require tight dimensional tolerances and high structural integrity, such as critical automotive or aerospace parts.

3D Printing as a Modern Casting Process

Three-dimensional (3D) printing, also known as additive manufacturing, has revolutionized the casting industry by enabling the production of complex geometries that are difficult or sometimes impossible to achieve with traditional methods. In this process, layers of material are deposited based on digital models, creating a detailed mold or pattern directly from computer-aided design data. Use cases such as investment casting now employ 3D printed wax or resin patterns that evaporate or burn out during the mold preparation stage, leaving an empty cavity in the exact shape desired for metal casting. This allows for precise control over internal channels and intricate features within cast parts without the need for manual craftsmanship or assembly of multiple pieces into one final pattern.

Q&A Section: Understanding Metal Types, Surface Finish Quality, and Process Selection in Casting

Different casting processes are compatible with various metals; for instance, aluminum, iron, steel, copper, and magnesium alloys are commonly utilized across methods such as die casting, sand casting, and investment casting. When it comes to achieving the finest surface finish, investment casting stands out due to its ability to produce components with high precision and excellent surface quality. Selecting the right casting process often depends on factors like the complexity of the design, material properties, tolerance requirements, and production volume – a thorough assessment ensures the ideal match between process capabilities and project needs. Not all casting techniques are suitable for large-scale production; high-volume demands are typically met by processes such as continuous or die casting, which cater efficiently to mass-production scenarios. In terms of cost-effectiveness, factors like tooling expenses, labor costs, and raw materials come into play; sand casting is frequently recognized as a more economical option for low to medium volumes, whereas the initial setup costs of die casting can be compensated by economies of scale during high-volume runs.